Full Description

View Full Description

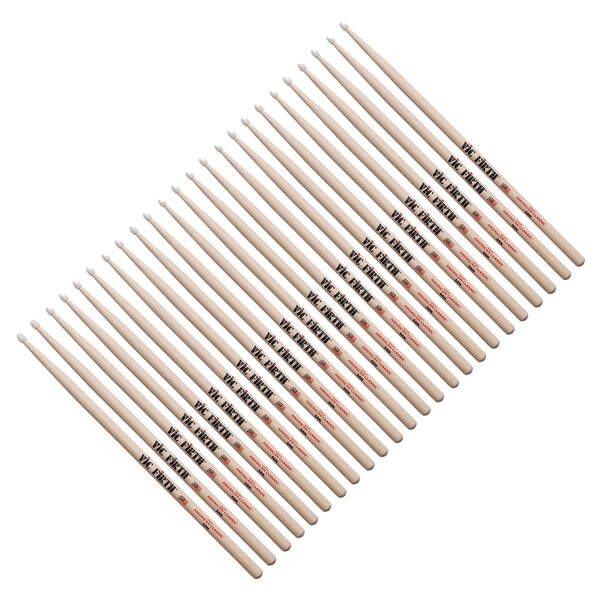

The world’s #1 drumstick choice

The Vic Firth 5A has probably been through more pro drummer’s hands than any other 5A out there on the market. That’s because no one else does sticks to the Vic Firth standard. When other sticks break, the Vic Firth 5A doesn’t even break a sweat. And that’s why everyone knows their name. Less stick-breaking mid-set means more time to groove in style.

Durable nylon tip

The Vic Firth American Classic 5AN Nylon Tip drumsticks go through an injection moulding process that was originally pioneered by Vic Firth. This allows for complex, precision shapes that match their wood tip counterparts exactly. They are more durable than a wood tip, so not only do they produce a more crisp, bright tone – they won’t let you down by chipping or coming off during a performance.

Backed up by science

You know that drumsticks are more than just pieces of wood for hitting drums. There’s a lot of science to it. Working on a regular basis with the wood science department at the University of Maine, and several other scientific organisations, Vic Firth put the quality of your drumsticks at the forefront of their operation.

It starts with the ideal hickory

There are 14 kinds of hickory and only 4 are ideal for drumsticks. Vic Firth uses the best of those 4 to make the American Classic Hickory drumsticks.

Then the vital first 6 steps of the manufacturing process

Most drumstick companies pick up the manufacturing process after these steps. Vic Firth understand the importance of getting these stages right.

- Vic Firth purchases green squares of wood

- This is fresh wood that hasn’t yet been dried. This allows Vic Firth to dry the wood themselves to achieve the desired result.

- The wood is cut to size

- All wood is cut to meet strict standards of consistency

- Dried in a kiln

- This is a heat and humidity controlled room that allows Vic Firth to reduce moisture in the wood to the ideal level for drumsticks. In turn, this prevents sticks from warping.

- Cut down into squares

- They are refined until perfectly uniform

- The squares are then reduced gradually to dowels

- Quality assured: They are weighed and measured using a laser to obtain consistent weight and profile.

- The dowels are then slowly reduced using a high-speed sanding process

- For the first time, this is when the wood starts to resemble drumsticks!

…And much more

There are many more steps in producing the perfect pair of drumsticks, but these are the key steps that set Vic Firth apart as a leading drumstick manufacturer. After 10 more steps of careful honing, refining, and then finishing, you finally have your much endeared Vic Firth American Classic 5A drumsticks. No one else invests that much time and energy in creating the perfect pair of sticks.

Read more about how Vic Firth drumsticks are made.

Not sure what sticks to buy? Find your perfect pair with the Vic Firth Drumstick Guide.

Specifications

- Size: 5A

- Quantity: Twelve pairs

- Diameter: 0.565’’

- Length: 16’’

- Material: Wood

- Tip Material: Nylon

- Tip Shape: Tear drop

- Taper: Medium

- Finish: Natural